Whether you're restoring a classic car, upgrading your vehicle with custom components, or simply replacing a discontinued part, 3D scanning and printing technology can be your best ally. Enter the 3D Maker Pro Mole 3D Scanner—a high-precision, user-friendly scanner that’s empowering DIY car enthusiasts, engineers, and professional tradespeople across the UK to scan, design, and replicate car parts at home or in small workshops.

Thanks to its plug-and-play software, compact size, and ability to capture very fine details, this scanner is the perfect companion for anyone looking to explore the world of automotive 3D printing without the complexity of industrial-grade equipment.

Why 3D Scan Your Own Car Parts?

Custom car work often demands precision. Whether you're tweaking an intake manifold, replicating a discontinued bracket, or fabricating a dashboard housing that integrates modern tech into a vintage car, accuracy is critical. Traditional measurement methods like calipers and manual modeling are time-consuming and prone to human error. That’s where a 3D scanner shines.

With the 3D Maker Pro Mole, you can scan existing parts and generate high-resolution 3D models suitable for editing, modification, or direct 3D printing. This accuracy not only saves time but also ensures parts will fit correctly the first time, reducing costly prototyping and frustration.

In automotive applications—where every millimeter matters—being able to clone or redesign a component digitally is a game-changer. From creating spoilers and fender flares to air filter mounts and interior trim pieces, the possibilities are endless.

Key Features of the 3D Maker Pro Mole

The Mole 3D Scanner is designed with usability and professional output in mind, all while keeping the price tag within reach for DIYers and small businesses. Here’s a breakdown of the core features that make it ideal for car part creation:

| Feature | Description |

|---|---|

| High Accuracy | Up to 0.05mm precision ensures detailed capture—even of small, complex geometries like threads or clip mounts. |

| Texture Scanning | Scans surface details including texture and colour—critical for matching interior trims or creating aesthetic parts. |

| USB Plug & Play | No complicated installations or commercial software – simple enough for beginners to use out of the box. |

| Portable Size | Perfect for tight garage spaces or mobile tradesmen conducting onsite work. |

| Wide Compatibility | Works with most CAD and 3D printing software like Fusion 360, Solidworks, and Meshmixer. |

Step-by-Step: Scanning and Reproducing a Car Part

If you’re new to 3D scanning, don’t worry. The process is simpler than it might sound. Here’s a step-by-step guide to help you get started with your first scanned and printed car part using the 3D Maker Pro Mole:

- Select the part: Choose a component you need, such as a plastic bracket, mirror cap, or trim piece. Clean it thoroughly—dust or oil on the surface can affect scan quality.

- Setup your scanner: Connect the Mole scanner to your PC or laptop using the included USB cable. Open the dedicated software and calibrate according to the prompts.

- Scan the object: Rotate the part slowly or use a turntable to ensure all angles are captured. Use the real-time preview to identify missed areas and re-scan if necessary.

- Edit the mesh: Once complete, export the file in .STL or .OBJ format. Use software like Blender or Tinkercad to clean up the mesh and make any design modifications.

- Export for printing or CNC: Send the model to a 3D printer or CNC machine to create the final part. Be sure to test fit the piece and tweak the model if adjustments are needed.

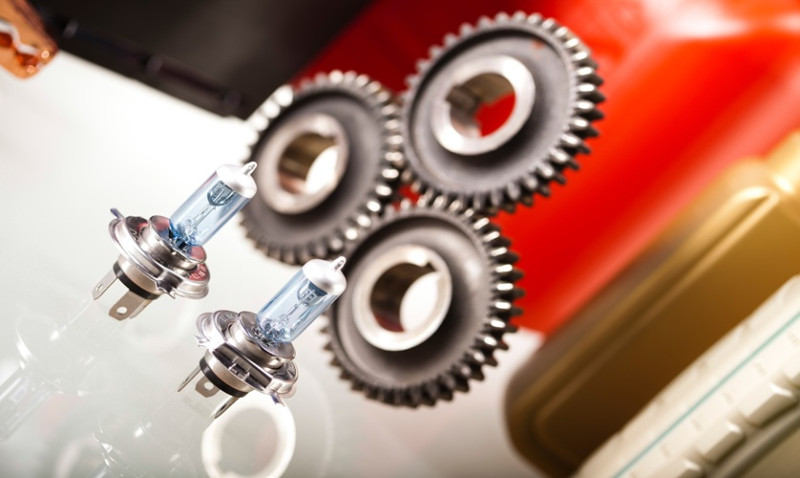

Real-World Applications: What Car Parts Can You Create?

Using the 3D Maker Pro Mole, DIY car enthusiasts and professionals across the UK have been able to recreate a variety of practical and stylish components, including:

- Plastic brackets and clips that are no longer manufactured

- Custom switch housings and dashboard panels

- Side mirror covers and light enclosures

- Vintage car knobs and interior trim restoration

- Air vents and AC ducting with custom designs

- Quick prototypes of performance parts for modification

The flexibility of scanning also means you can take inspiration from one part and modify it—say, extend a battery holder or reshape a panel—for a truly custom solution.

Who Is This Tool For?

While the Mole 3D Scanner is great for car enthusiasts and professionals alike, it also suits a broader group. Young homeowners interested in DIY garage culture, local mechanics trying to offer custom services, and even industrial designers needing digital part archiving can all benefit.

Architects and designers may be surprised by the Mole's capabilities, especially when working on themed interiors or automotive-styled home décor, like garages converted into man-caves or showrooms for car collections.

From single-use hobby tasks to daily use in a workshop or scanning service business, this scanner adapts to your workflow without the steep learning curve.

Tips for Best Results When Scanning Car Parts

Here are a few expert tips to ensure you get the best quality scans:

- Use matte spray on reflective or transparent parts – This prevents errors in scan data capture.

- Control your lighting – Avoid direct sunlight and opt for diffused lighting to reduce interference.

- Take multiple scans if needed – Stitch together different angles using the software’s alignment tools.

- Don’t rush post-processing – Take time to smooth, fill holes, and align edges before printing.

Conclusion: Take Control of Your Custom Car Projects

The 3D Maker Pro Mole 3D Scanner brings powerful scanning capabilities directly into your hands. Whether you’re a weekend garage tinkerer, a professional looking to offer custom solutions, or a designer pushing the boundaries of automotive style, this tool unlocks a new level of creativity and precision in your workflow.

Creating your own car parts is no longer reserved for massive engineering warehouses. You can now measure, model, and manufacture—all from your garage in Leeds, workshop in Manchester, or studio in London. Bring your imagination to life and keep your projects on the road (or showroom floor) with 3D scanning on your side.

Ready to get scanning? It’s time to take your car transformations into your own hands.